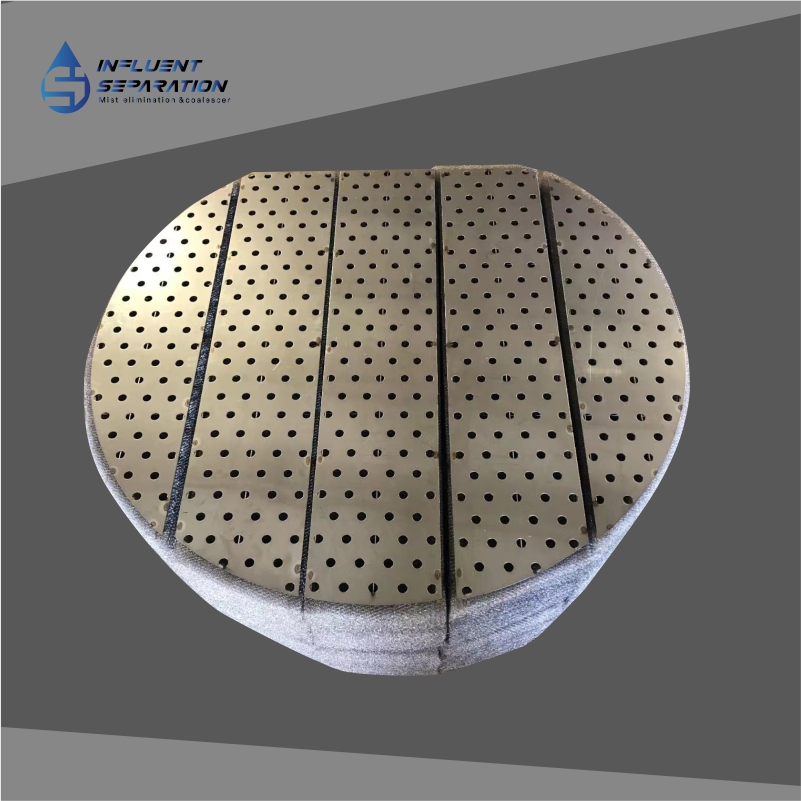

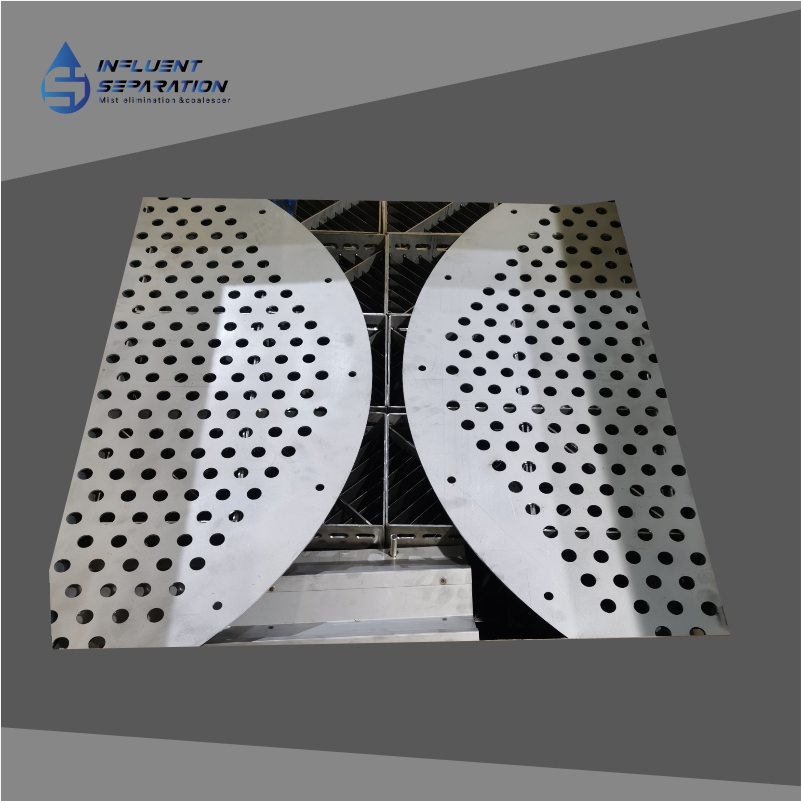

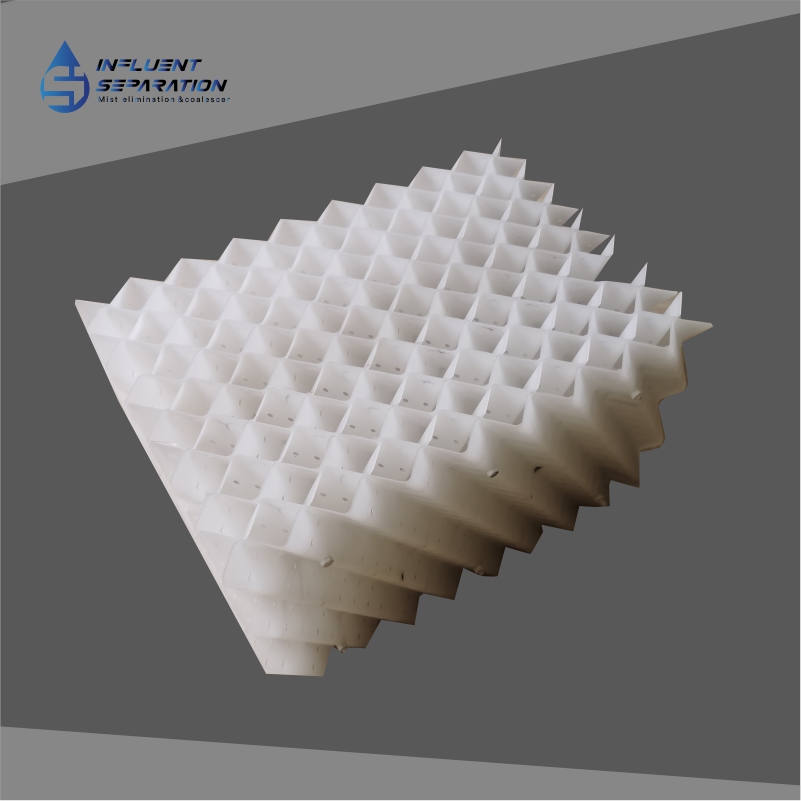

Calming Baffles (Perforated Plates)

03/13/2023

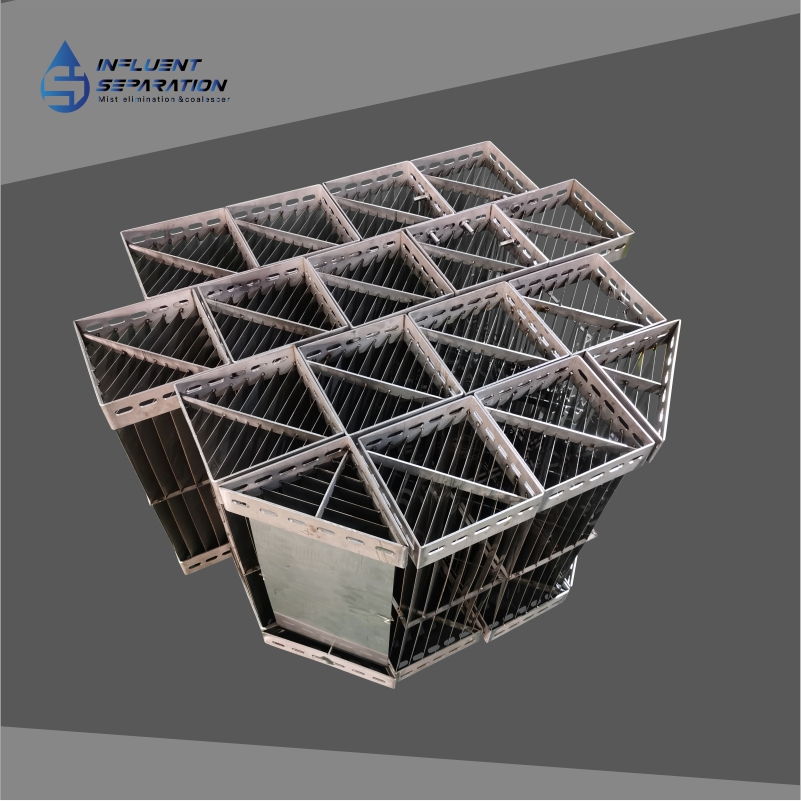

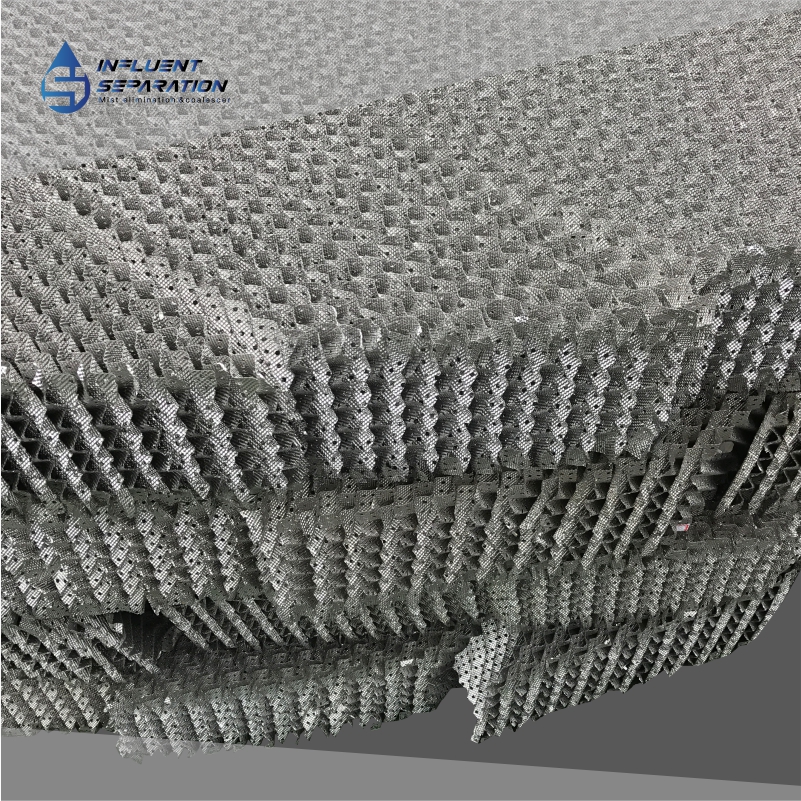

Plate Pack Separator Media

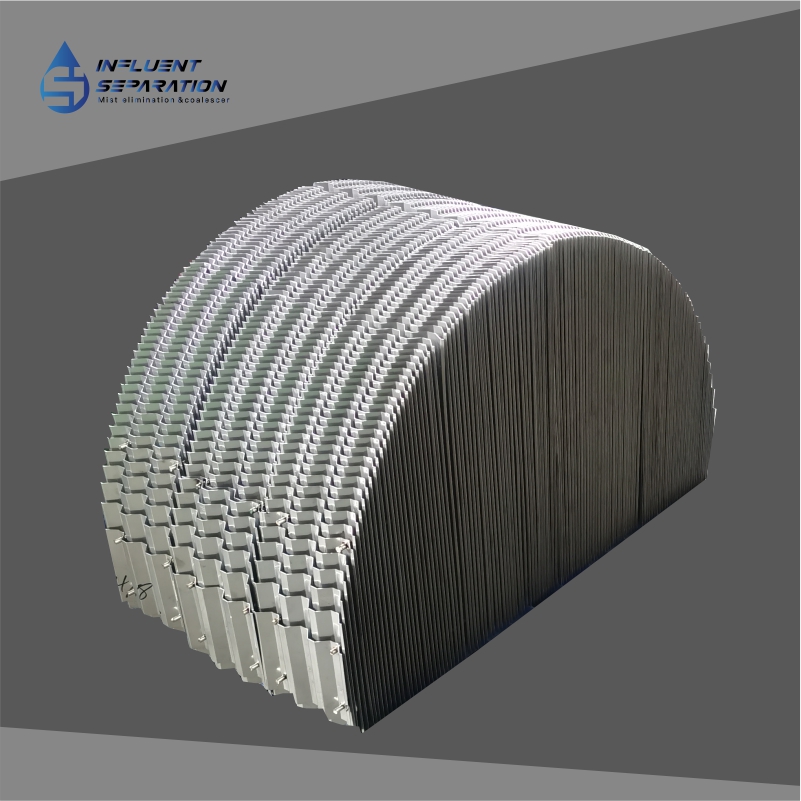

03/15/2023Knitted Wire Mesh Coalescer Media

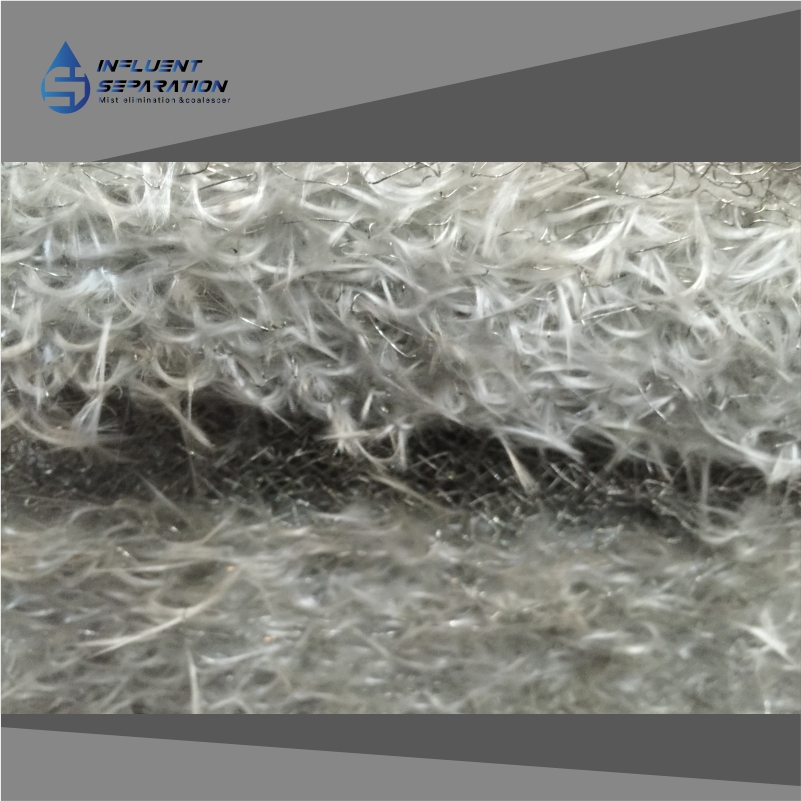

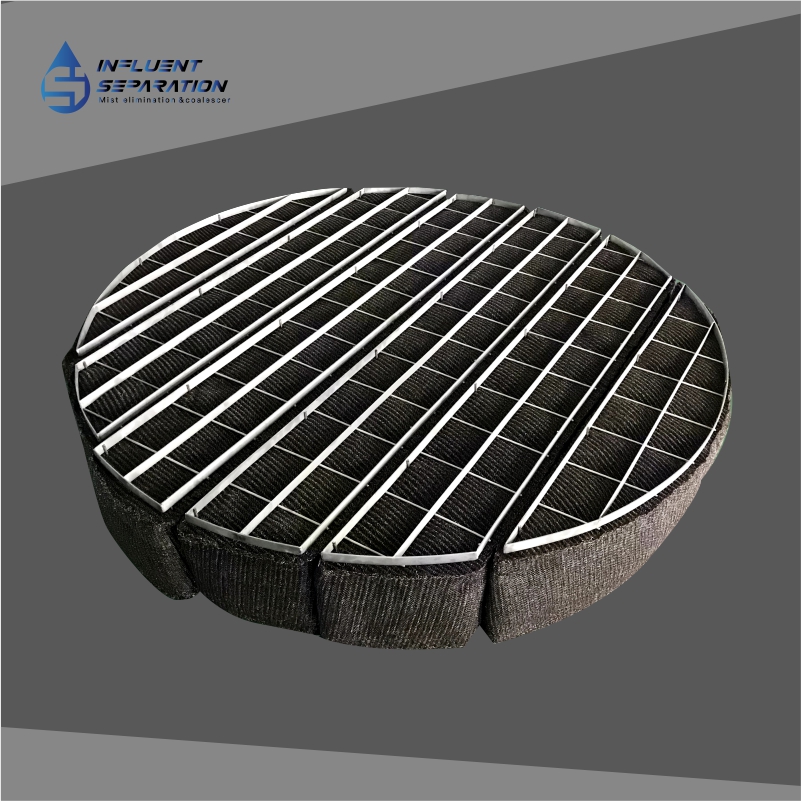

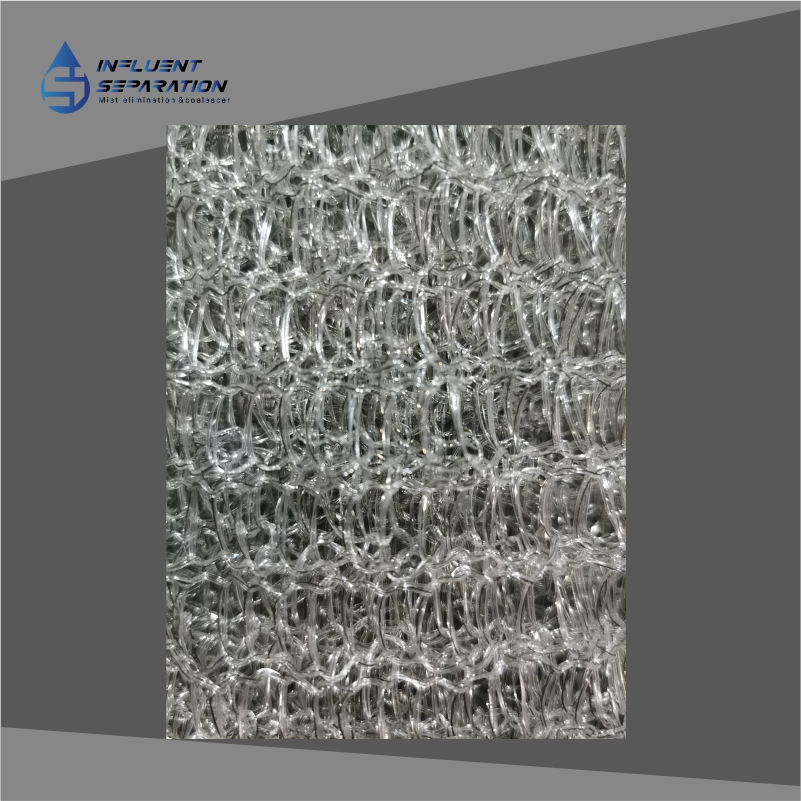

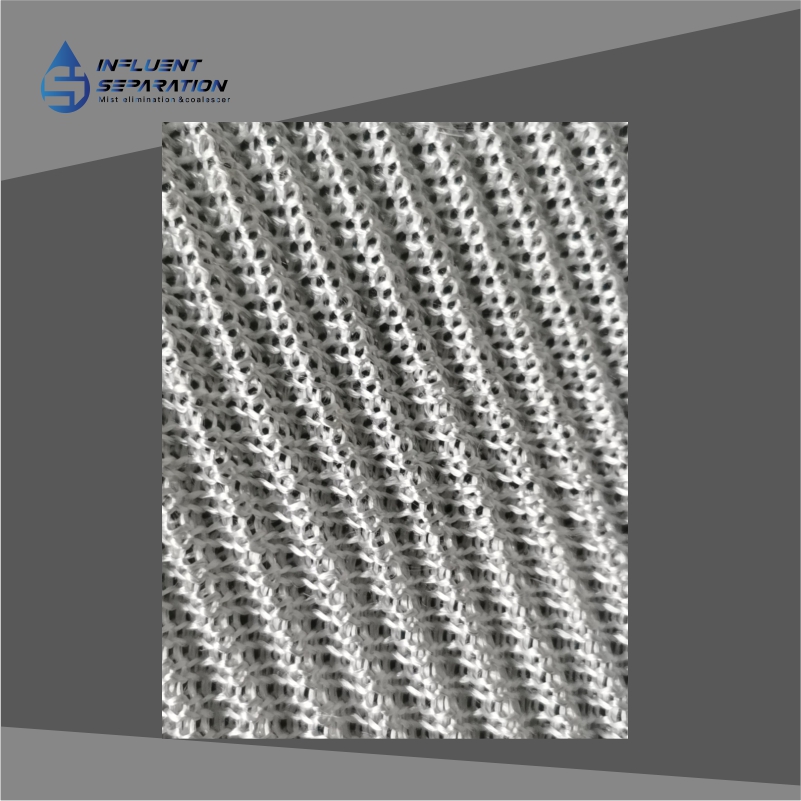

Item Name: Knitted Wire Mesh Coalescer Media

Materials of Construction

• Stainless steel, duplex steel

2205,2507,254SMO

• Alloy C276, 400, 625, 825, 20, etc…

• Plastics (PP, FEP, ETFE, PVDF, PFA)

• Fibrous components (Teflon®PTFE Fibers,

Polyester, Glass fibers, Nylon)

This passage describes the process of separating dispersed droplets in a fluid stream by using a wire mesh liquid-liquid coalescer as a polishing stage. The coalescer works to increase the size of the droplets, making them easier to settle downstream. This process is particularly effective for smaller droplets that settle slowly or not at all, often referred to as secondary dispersions, haze, or emulsions.

To address these challenges, high-performance coalescing media can be custom-engineered to suit the specific properties of the chemicals involved. Once the fluid flow leaves the coalescer, it enters a settling zone where the coalesced droplets settle from the liquid stream towards the interface.

Overall, this passage highlights the importance of effective separation techniques in industrial processes that involve complex chemical mixtures. Using specialized equipment and custom-engineered solutions makes it possible to achieve highly efficient separation and purification of valuable chemicals and substances.

Knitted wire mesh coalescer media is a type of filter media used for liquid-liquid separation processes. It consists of a knitted wire mesh structure that is designed to capture and coalesce small droplets of one liquid phase suspended in another liquid phase. The coalesced droplets then become larger and easier to separate from the main liquid phase.

The knitted wire mesh structure of the coalescer media provides a large surface area for the liquid to flow through, increasing the chances of droplet capture and coalescence. The size and shape of the mesh can be customized to achieve optimal performance for a specific application.

Coalescer media can be used in a variety of liquid-liquid separation applications, including oil-water separation, solvent recovery, and chemical processing. They are often used in the oil and gas industry to remove oil from water or gas streams, as well as in the pharmaceutical and chemical industries for separating immiscible liquids.

Overall, knitted wire mesh coalescer media is an effective and versatile filter media for liquid-liquid separation processes, offering high efficiency and long-lasting performance.

| Co-Knit Type | |||||||

| Material | Type Number |

Free Volume |

Density | Specific Surface Area | Equal to | ||

| (lb/ft³) | (kg/m³) | (ft²/ft³) | (m²/m³) | ||||

| Metal/fiberglass | MAX®ISM7374(M) | 96.45% | 12.5 | 200 | 2248 | 7374 | |

| Metal/fiberglass | MAX®ISM1500(M) | 93.00% | 12 | 195 | 457 | 1500 | |

| Metal/fiberglass | MAX®ISM1000(M) | 95.00% | 8 | 135 | 305 | 1000 | |

| Metal/Polypropylene Fibers | MAX®ISM4809(M) | 95.00% | 8 | 135 | 1466 | 4809 | |

| Metal/Nylon Fibers | MAX®ISM6400(M) | 93.20% | 13 | 200 | 1951 | 6400 | |

| Polypropylene Fibers/Polypropylene | MAX®ISM4662(M) | 92.80% | 4 | 64 | 1421 | 4662 | |

| Metal/PTFE | MAX®ISM548 | 96.00% | 13 | 200 | 167 | 548 | |

| Metal/Teflon®PTFE Fibers | MAX®ISM6830(M) | 93.50% | 20 | 320 | 2082 | 6830 | |

| Metal/Teflon®PTFE Fibers | MAX®ISM3630(M) | 96.30% | 13 | 200 | 1107 | 3630 | |

| Metal/Polyester Fibers | MAX®ISM2290(M) | 96.35% | 12 | 192 | 698 | 2290 | |

You must be logged in to post a review.

Reviews

There are no reviews yet.