GAS-LIQUID SEPARATION

Droplet Formation

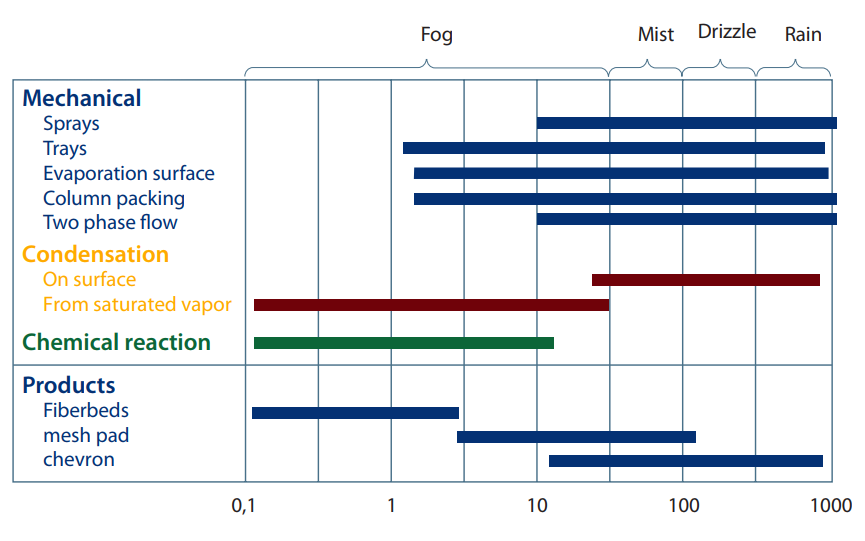

The below table gives an overview of the different sources of droplet formation and an indication on the respective range of droplet size, as well as an overview of the efficiency of the different types of mist

DEFINITIONS OF WORDS AND PHRASES USED IN

SEPARATION EQUIPMENT

• Entrainment:

Fluid in the form of a mist, fog, droplets, or bubbles

carried along with the continuous phase

• Coalescing:

To come together to form a larger whole. The process or

mechanism of bringing small droplets or aerosols and

creating larger droplets that can more easily be removed

by gravity. Also refers to the joining of liquid droplets

dispersed in another immiscible liquid, as with water

drops in oil.

• Mist eliminator:

A fixed device used to enhance removal of smaller liquid

droplets from a gas above which is not normally possible

by gravity separation. Typical mist eliminator

designs include knitted wire mesh, vane type, and cyclonic.

Mist elimination internasls provided by InfluentSeparation

prove to be an effective solution to eliminate the droplet

entrainment problems in typical applications as follows:

• Gas and oil processing

• Refinery units (crude unit, FCC,SRU, alkylation)

• Environmental scrubber, absorption tower

• Evaportators,condensers

• Sulphuric acid

• Fuming acid mist removal

• Chlor-alkali

• Nitric acid

• Methanol,Ethylene

• Ammonia and urea

• Asphalt vent mist removal

• Lube oil mist removal

• Metalworking mist removal

• Pulp & paper

• .......

A wide variety of separation vessel styles

and devices are used in the natural gas

processing industry. These include vertical and

horizontal vessels, two and three phase, many

types of internals, as well as cyclonic devices,

filter separators, gas coalescing filters, and

gas and liquid filters.