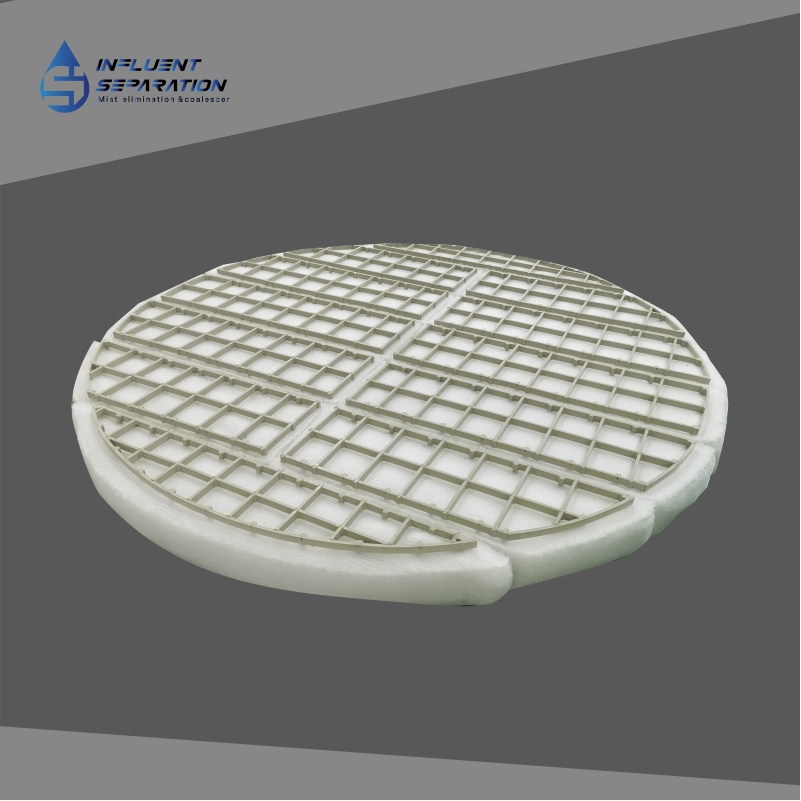

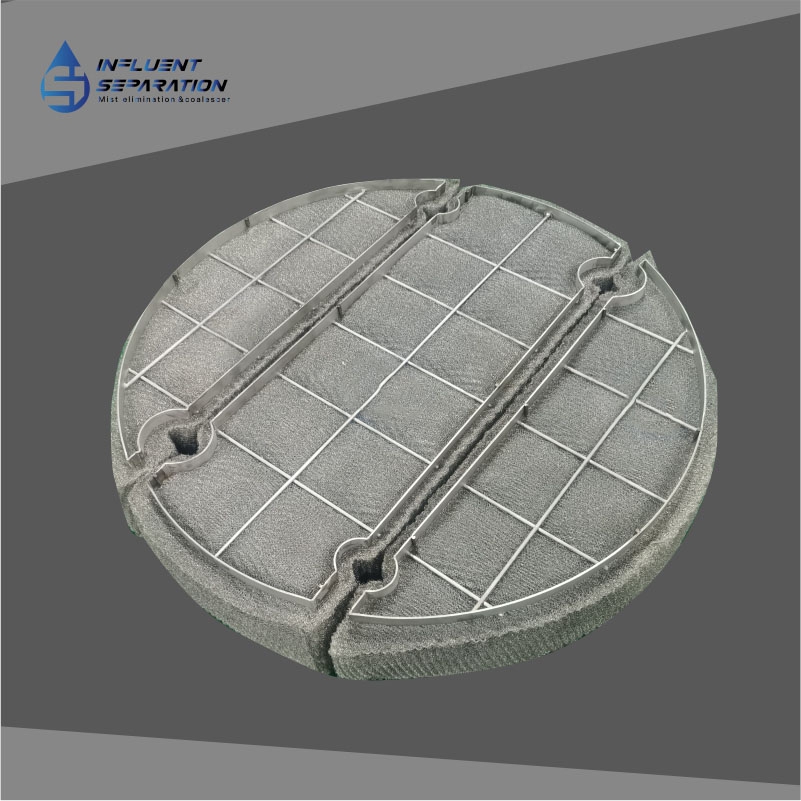

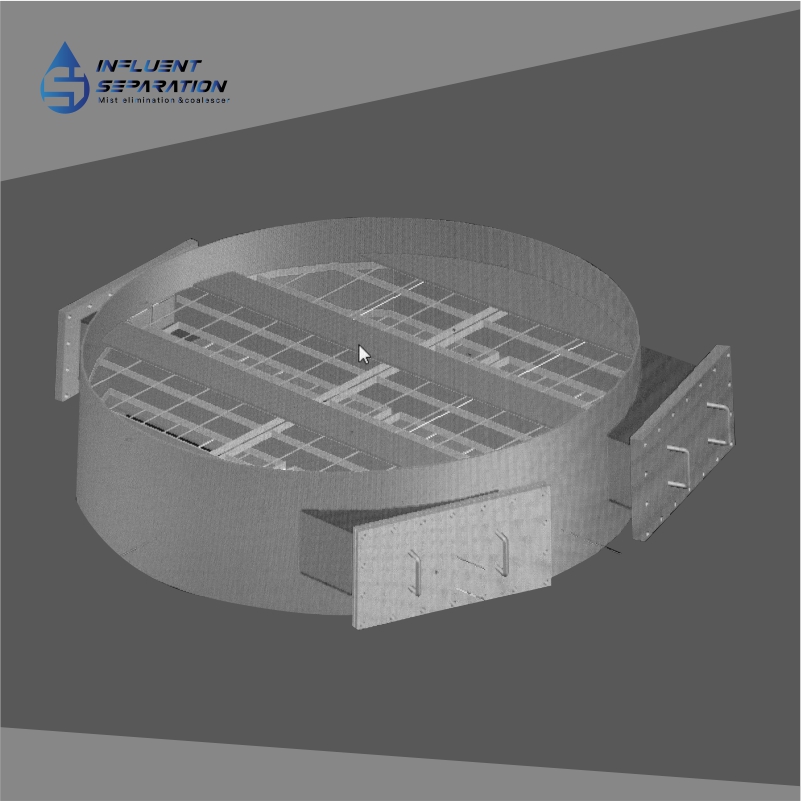

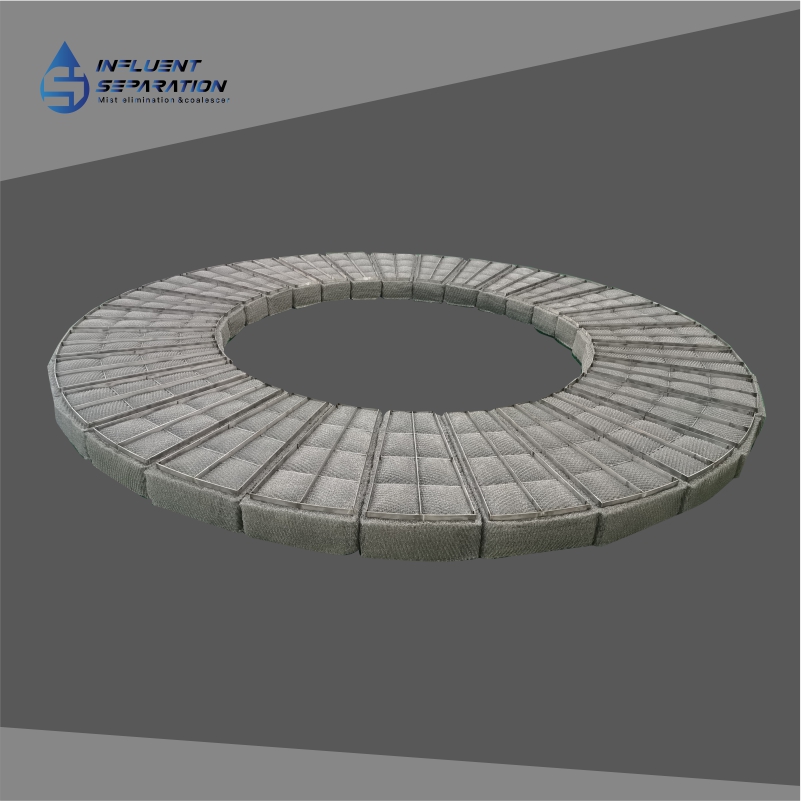

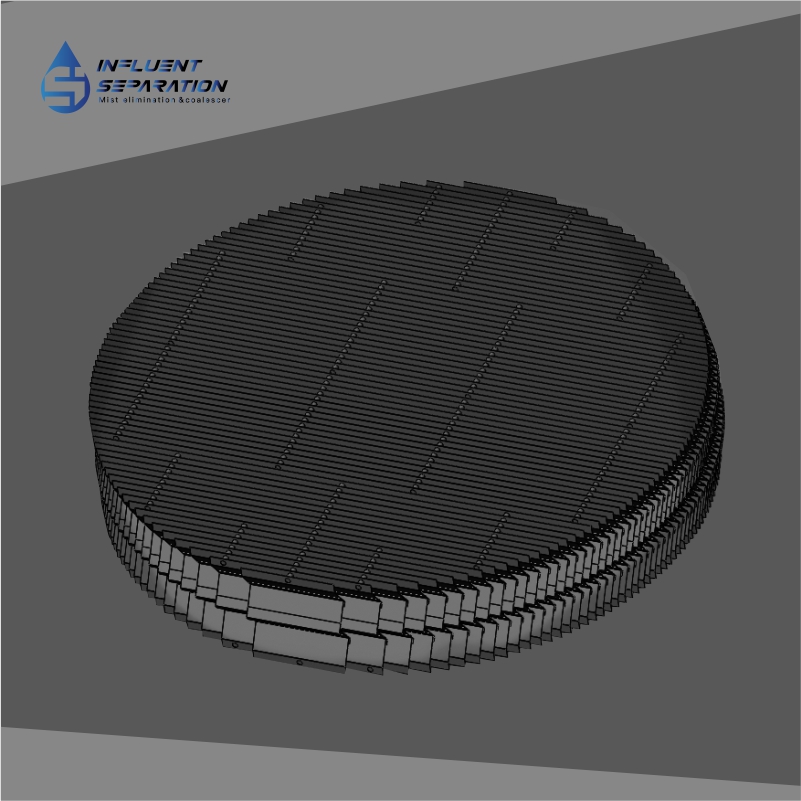

Title: Demister Knitted Wire Mesh Mist Eliminator – Product Introduction

Introduction:

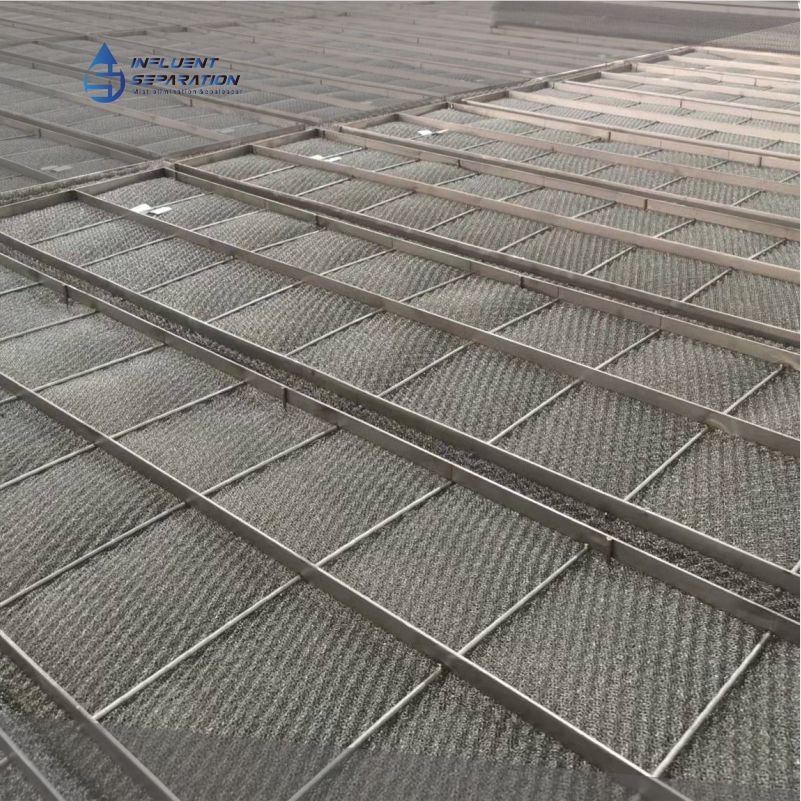

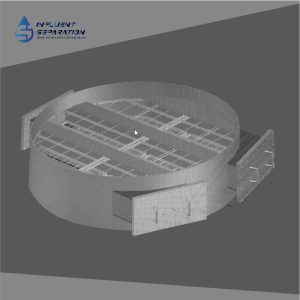

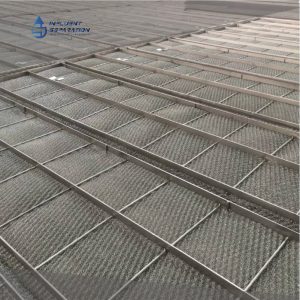

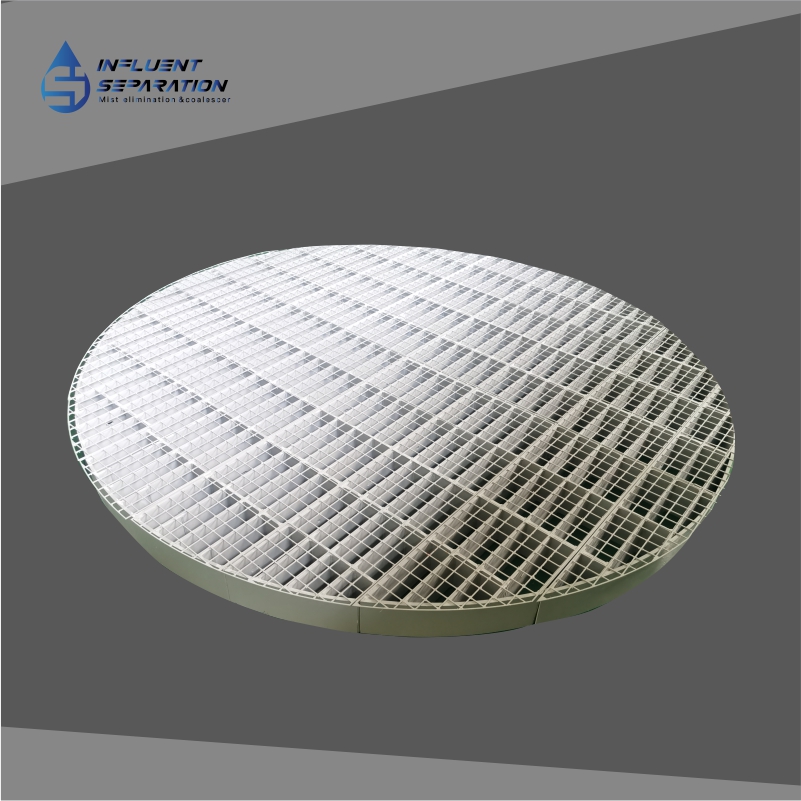

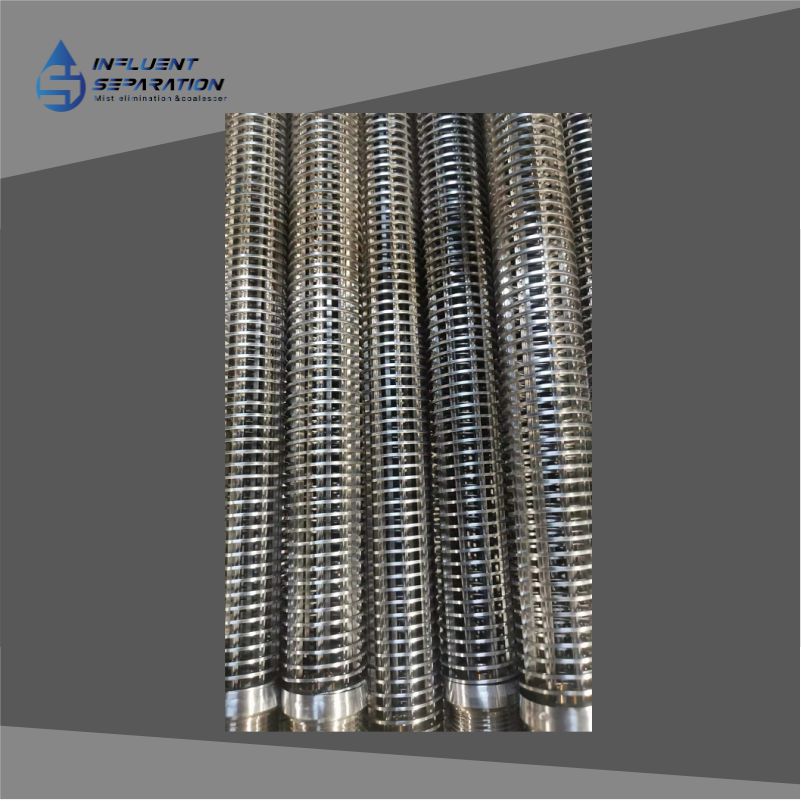

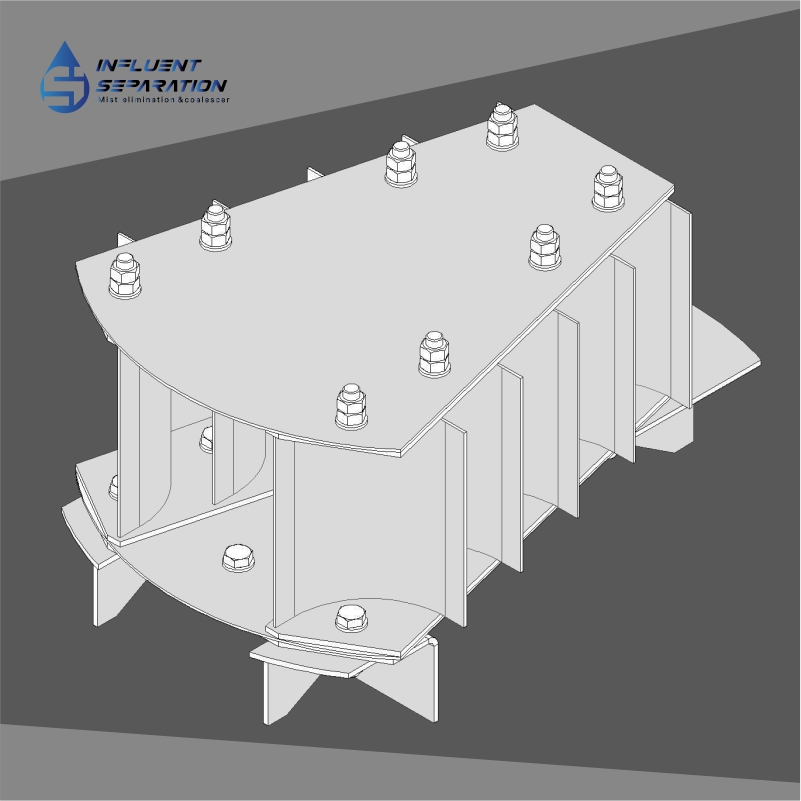

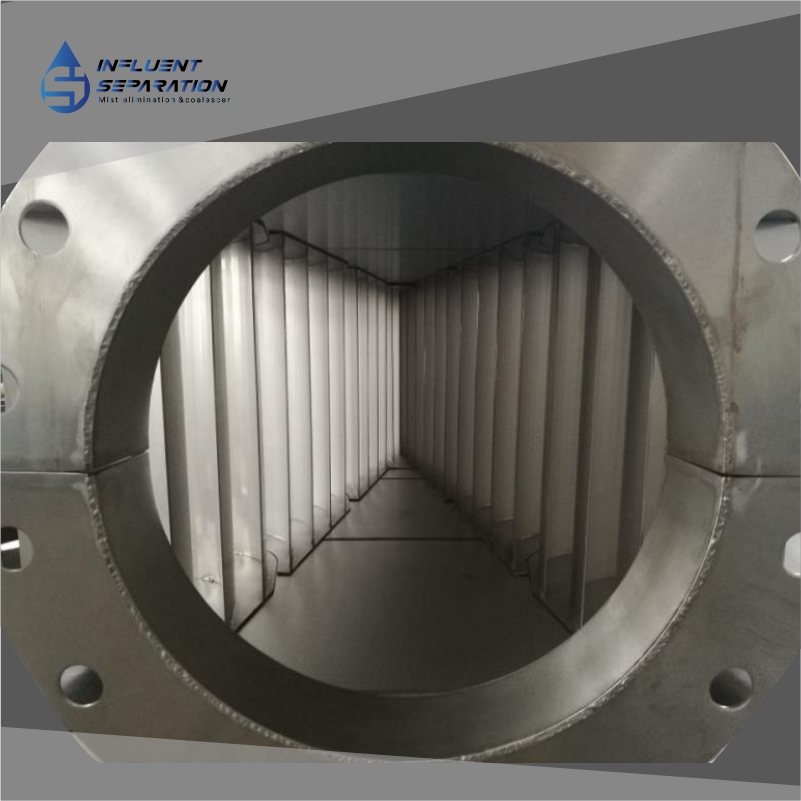

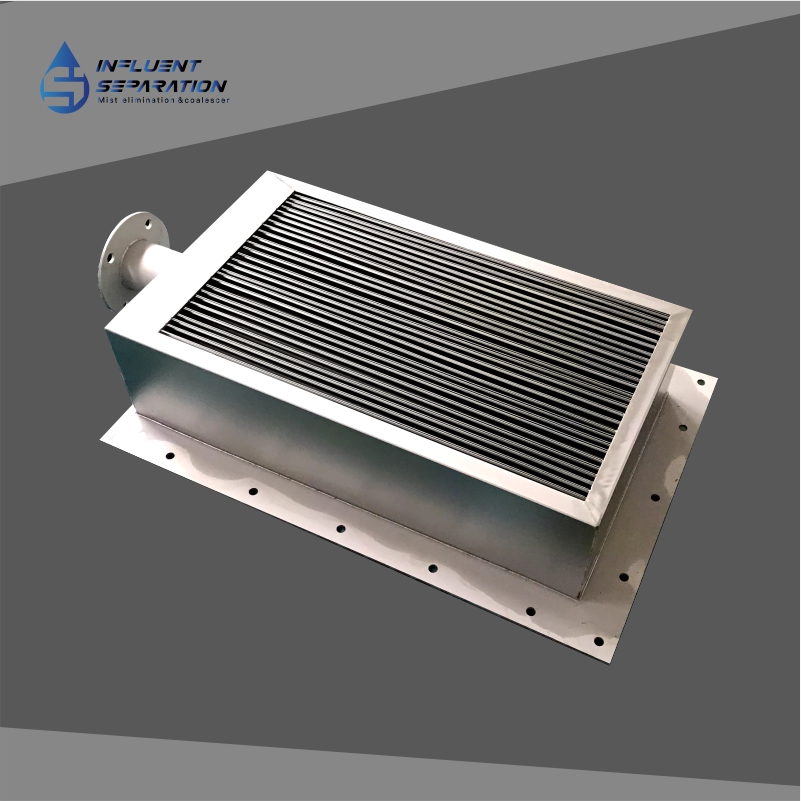

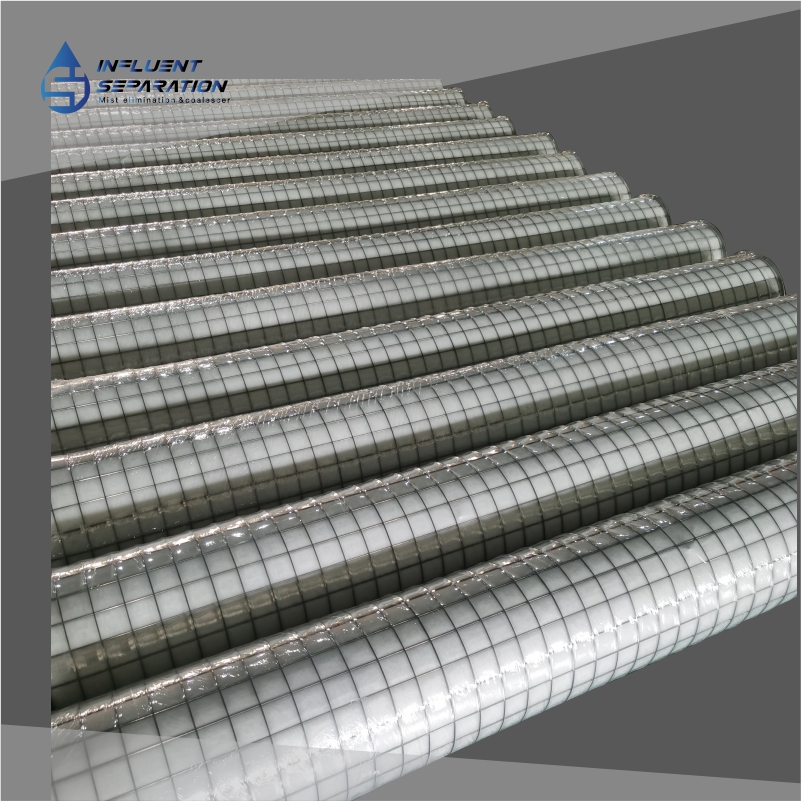

Demister Knitted Wire Mesh Mist Eliminator is a highly efficient and cost-effective solution for removing mist and droplets from gas streams. It is designed to capture and eliminate liquid droplets that are present in gas streams, such as in the chemical, petrochemical, and oil and gas industries. The knitted wire mesh structure provides a high surface area for efficient separation and allows for a low-pressure drop, making it an ideal choice for various gas-liquid separation applications.

Features and Benefits:

- High Efficiency: Knitted Wire Mesh Mist Eliminators have a high removal efficiency for mist and droplets, up to 99% for droplets larger than 3 microns.

- Low-Pressure Drop: The low-pressure drop of the mesh pad allows for a reduction in energy consumption and can save costs in the long run.

- Corrosion Resistance: The wire mesh is made of materials such as stainless steel, nickel, and other alloys that provide excellent corrosion resistance, making it suitable for use in harsh environments.

- Customizable: Knitted Wire Mesh Mist Eliminators can be designed to fit specific needs and requirements, including size, shape, and materials.

Applications:

Demister Knitted Wire Mesh Mist Eliminators are commonly used in various industries, including:

- Chemical industry: For the separation of acid mists, ammonia mists, and other harmful gases.

- Petrochemical industry: For the separation of hydrocarbon mists and other volatile organic compounds.

- Oil and gas industry: For the separation of water droplets and other impurities from natural gas.

- Pharmaceutical industry: For the separation of fine droplets and powders from gases in the manufacturing process.

Conclusion:

Knitted Wire Mesh Mist Eliminators are a reliable and cost-effective solution for gas-liquid separation applications. The high efficiency and low-pressure drop make it an ideal choice for various industries, including chemical, petrochemical, and oil and gas. With customizable options, it can be tailored to specific needs and requirements, making it a versatile option for different applications.

| Wire Mesh pad Type Selection |

| Metal |

| Material |

Type

number |

Free

volume |

Density |

Specific Surface Area |

|

Equal to |

| (lb/ft³) |

(kg/m³) |

(ft²/ft³) |

(m²/m³) |

|

| Stainless steel |

MAX®ISM643(M) |

97.59% |

12 |

192 |

196 |

643 |

|

| Stainless steel |

MAX®ISM356 |

97.50% |

12 |

192 |

109 |

356 |

york421 or 9033 |

| Stainless steel |

MAX®ISM208 |

98.60% |

7 |

112 |

63 |

208 |

|

| Stainless steel |

MAX®ISM148 |

99.00% |

5 |

80 |

45 |

148 |

york931 or 9036 |

| Stainless steel |

MAX®ISM267 |

98.00% |

9 |

144 |

81 |

267 |

york431 or 9030 |

| Stainless steel |

MAX®ISM484 |

98.00% |

9 |

145 |

148 |

484 |

|

| Stainless steel |

MAX®ISM434 |

98.37% |

8 |

130 |

132 |

434 |

york326 |

| Stainless steel |

MAX®ISM721 |

97.29% |

14 |

216 |

220 |

721 |

|

| Stainless steel |

MAX®ISM408 |

97.24% |

14 |

220 |

124 |

408 |

|

| Stainless steel |

MAX®ISM1804(M) |

94.59% |

27 |

432 |

550 |

1804 |

york333 |

| Stainless steel |

MAX®ISM1470(M) |

94.49% |

28 |

440 |

448 |

1470 |

|

| Titanium |

MAX®ISM284 |

98.22% |

5 |

80 |

87 |

284 |

|

| Non-Metalic |

| Polypropylene |

MAX®ISM1178 |

92.45% |

5 |

74 |

359 |

1178 |

york241 |

| Polypropylene |

MAX®ISM653 |

93.47% |

4 |

64 |

199 |

653 |

|

| Polypropylene |

MAX®ISM326 |

96.73% |

2 |

32 |

99 |

326 |

|

| PTFE |

MAX®ISM750 |

94.40% |

8 |

135 |

229 |

750 |

|

| FEP |

MAX®ISM1050 |

92.65% |

11 |

180 |

320 |

1050 |

|

| PVDF |

MAX®ISM1031 |

92.78% |

8 |

130 |

314 |

1031 |

|

| ETFE |

MAX®ISM390 |

95.00% |

4 |

59 |

119 |

390 |

|

| PE |

MAX®ISM440 |

94.49% |

3 |

54 |

134 |

440 |

|

| PFA |

MAX®ISM874 |

93.88% |

9 |

150 |

266 |

874 |

|

Reviews

There are no reviews yet.