Wire Mesh Demister: The Common Mist Eliminator for Industrial Processes

03/19/2023Demister Pads for Evaporators: Applications, Installation, and Maintenance Guide

02/16/2025When it comes to industrial equipment, the efficient separation of gas and liquid is crucial for ensuring smooth and safe operation. That’s where vane packs and mist eliminators come in. These devices are designed to remove mist and droplets from gas streams, preventing them from damaging downstream equipment or affecting product quality.

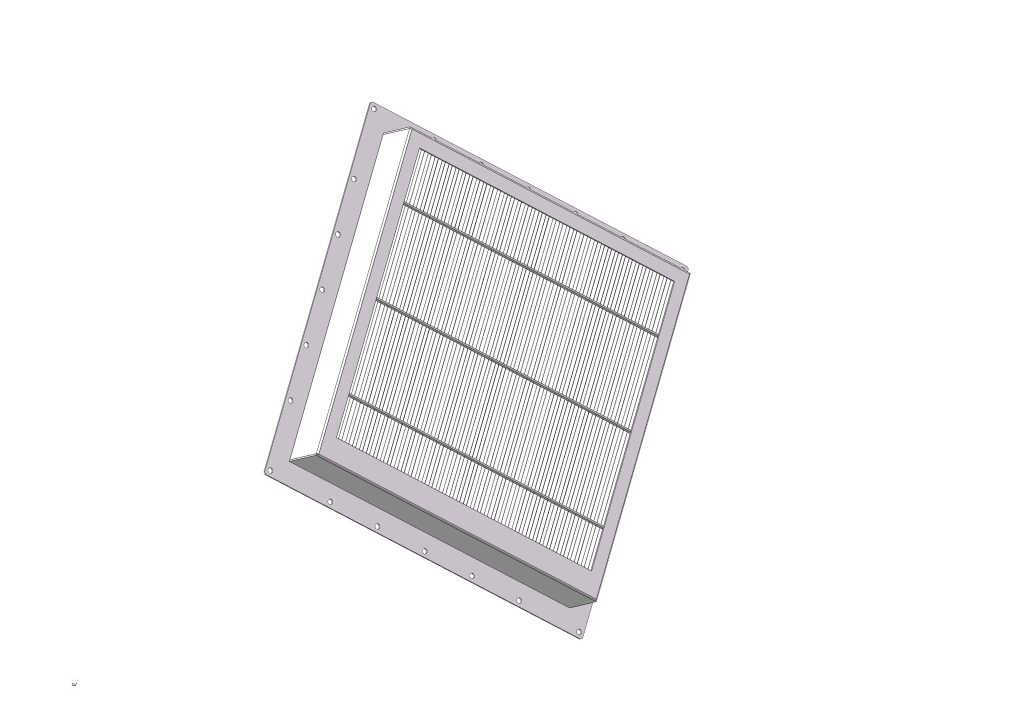

Vane packs are one type of mist eliminator that works by using a series of vanes or blades to force gas and liquid to change direction. As the gas and liquid change direction, the liquid droplets collide with the vanes and coalesce, eventually falling out of the gas stream. Vane packs are commonly used in vertical separators, knockout drums, and scrubbers.

Another type of mist eliminator is the chevron mist eliminator. This device uses a series of chevron-shaped plates to create a tortuous path for the gas stream. As the gas flows through the plates, the droplets collide with the plates and coalesce, eventually falling out of the gas stream. Chevron mist eliminators are commonly used in horizontal separators and scrubbers.

Both vane packs and chevron mist eliminators are effective at removing mist and droplets from gas streams, but which one is best for a given application depends on factors such as the gas flow rate, the liquid load, and the equipment dimensions.

Overall, using vane packs and mist eliminators is an essential step in ensuring the safe and efficient operation of industrial equipment. By preventing liquid droplets from reaching downstream equipment or products, these devices can help reduce downtime, maintenance costs, and product quality issues