Design of a Wire Mesh Demister

03/19/2023Vane Packs and Chevron Mist Eliminators: Essential Equipment for Efficient Gas-Liquid Separation

03/19/2023

In many industrial processes, mist and droplets are generated as a result of various operations such as distillation, absorption, and evaporation. These mists and droplets can have adverse effects on the efficiency of the process as well as on the environment. Therefore, it is essential to remove these mist and droplets from the process stream.

Wire mesh demisters, also known as mist eliminators, are the ultimate solution to this problem. These devices are widely used in various industries, including chemical, petrochemical, and pharmaceutical, to remove mist and droplets from the process stream.

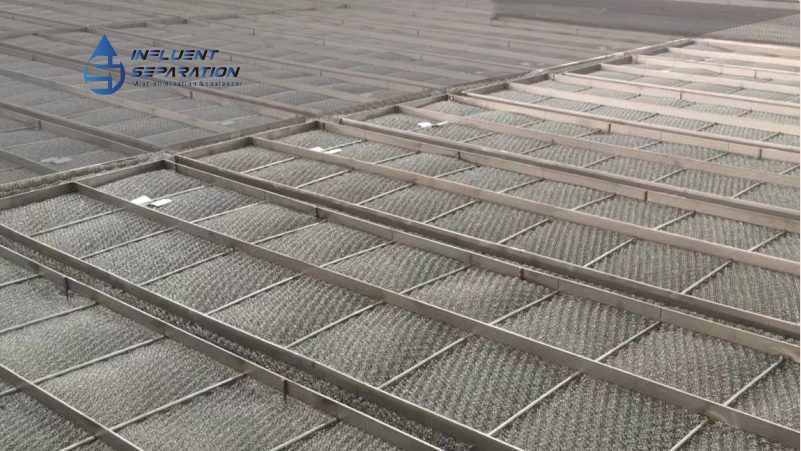

Wire mesh demisters consist of a mesh pad made up of layers of knitted wire mesh. The mesh pad is installed in the process stream, and as the mist and droplets pass through it, they collide with the wire mesh and coalesce into larger droplets. These larger droplets then fall back into the process stream, leaving the gas or vapor free of mist and droplets.

The wire mesh demister is a highly efficient device that can remove mist and droplets up to 99.9% from the process stream. It is also very easy to install and maintain, making it a cost-effective solution for mist and droplet removal.

Wire mesh demisters are available in various configurations and materials to suit different process requirements. The wire mesh can be made up of various materials such as stainless steel, Monel, and polypropylene. The pad can also be customized to suit different process conditions such as high pressure, high temperature, and corrosive environments.

In conclusion, wire mesh demisters are the ultimate mist eliminators for industrial processes. They are highly efficient, cost-effective, and easy to install and maintain. If you are looking for a solution to remove mist and droplets from your process stream, wire mesh demisters are the answer. Contact your trusted supplier today to learn more about wire mesh demisters and how they can benefit your process